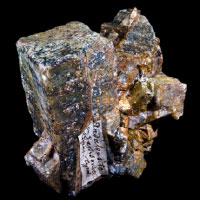

Andalusite is an alumina-silicate raw material used principally in the manufacture of heat resistant refractory bricks. When andalusite is produced, unlike many other refractory raw materials, costly calcining is not required. Typical physical/chemical characteristics of the Peruvian andalusite are 59% Al2O3 and Fe2O3 0.80%.

a)Andalusite conversion to mullite at relatively low temperatures, imparting high hot strength and resistance to physical-chemical erosion, with very good resistance to slag penetration and alkali attack.

a)Andalusite conversion to mullite at relatively low temperatures, imparting high hot strength and resistance to physical-chemical erosion, with very good resistance to slag penetration and alkali attack.

b) Minimum volume change when firing andalusite-containing refractory materials; dimension control of the refractory is improved.

c) High creep and abrasion resistance, high strength at high temperatures, resistance to chemical and physical erosion.

d) The very low volume change on firing is also advantageous when andalusite is used in monolithic refractories.

e) Resistance to attack and penetration by slag and gases.

f) The low flux content helps the resistance to slags and alkalies

Applications

Used as main raw material in porcelain and hardfired superduty bricks, spark plug porcelain, high heat resist wool, automotive brakes, cookware, abrassives , refractary industry. Also principally in iron and steel making, mostly in monolithic linings in blast furnaces, stove brick and checkers, torpedo transfer, hot metal mixers, casting ladles, and induction furnaces, Andalusite shapes are used in cement kilns, the glass industry, in and in induction furnaces.

Used as main raw material in porcelain and hardfired superduty bricks, spark plug porcelain, high heat resist wool, automotive brakes, cookware, abrassives , refractary industry. Also principally in iron and steel making, mostly in monolithic linings in blast furnaces, stove brick and checkers, torpedo transfer, hot metal mixers, casting ladles, and induction furnaces, Andalusite shapes are used in cement kilns, the glass industry, in and in induction furnaces.

Andalusite refractories are also used effectively under abrasive conditions where high loads and high temperatures exist also in stack linings and kiln furniture, monolithic castable linings, ramming mixes and heat exchangers, heat treatment furnaces.